Cooling towers are used to remove waste heat from a process by releasing it to the atmosphere. Cooling is necessary for a steam cycle to continue to operate due to equipment and thermodynamic limitations. In some ways, a cooling tower is analogous to the radiator on an automobile.

WHY OCTAGON COOLING TOWER?

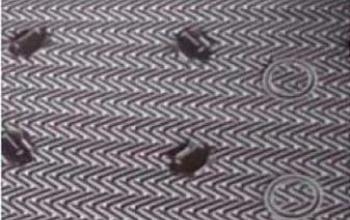

Fill & Drift Eliminator Design

- Energy cost, the thermal design point, and water quality are example of factor which influence the choice of fill.

- This fill is thermally vacuum formed from rigid polyvinyl chloride (PVC). The fill will be able to withstand temperature of up to 52 C. Integral drift eliminator and louvers keep circulation water confined to fill over a wide range of flowrates. The drift loss is less than 0.005% of the cooling tower design flowrate.

- Patented waved fill design significantly increases cooling tower efficiency as its expansive surface area accelerates cooling. This increased efficiency translates to reduced pump head and horsepower requirements. The special configuration of the filler incorporate the function of drift eliminator, louver and heat exchanging surface, make TYH be more compact. The honeycomb shaped louver feature contributes minimum resistance to airflow.

High Efficient Fan

- Fabricated are from Aluminum Alloy. Fan hubs are fabricated with hot-dip galvanized circular plate. The aerodynamic shape together with the lower tip speed ensure a lower noise level. The fan are adjustable for in pitch for permitting maximum utilization of rated horsepower and optimum performance

- Advantages: High efficiency, lower tip speed, light weight, low power consumption, low noise, low vibration

Mechanical Part

- Dynamic balanced pulleys ensure quiet operation and low vibration.

- Totally enclosed bearing with heavy duty self-aligning ball type is designed for a minimum of75,000 hours life span. Cast iron housing and flexible cap protect the bearing from extremeenvironmental attack such like rain, vibration and various kind of impact.

Space & Cost Savings

- Large Single Cell concept and option for internal piping save space and additional piping and instrumentation.

Efficient Water Distribution

- Polypropylene Target Nozzles are essential to ensure maximum water distribution overthe fills

Proven Installation & Reliability

- Octagon have been installed in numerous prestigious buildings and factories

- Customer satisfaction testified by its long list of proven installation

Easy Access For Services

- Easy access for routine inspection and maintenance. HDG Steel plenum walkway is a standard accessory.

Corrosion Resistance

- The casing, hot and cold water distribution basins are made of FRP (an excellent non-corrosive material

- The frame and other steel sections are hot dip galvanized to ensure corrosion resistance (Stainless steel structure available as option)

Low Maintenance Cost

- Heavy Duty aluminum alloy fans, fan bearing and stainless steel fan shafts require only periodic maintenance

- Low maintenance materials are used throughout the cooling tower

- Wide spaced flow fill helps prevent clogging

- The fills are easily accessible for cleaning

Right Angle Gearbox Drive Option

- Gearbox Drive Option in lieu of Belt Drive System is readily available for cooling tower that requires rugged and continuous operation.

After Sales Service

- Octagon provides quality maintenance, service and refurbishment for all types of cooling tower